Nano (PVDF) panel

Nanometer panel inherits all features of the traditional PVDF panel, which include antipollution, cauterization resistance and fastness. However the Nanometer high technology also includes the function of self-cleaning and is acid and alkali-resistant. Therefore, the Nano Panel has better self-cleaning functions than compared with the traditional PVDF panel.

Typically when an aluminum composite panel is used for exterior walls after duration of 6 months, the surface becomes badly polluted by lasting effects of dust and rainwater. In particular, if inferior silicone sealant is used between panel seams this may result in black marks following the effects of pollution and rain water. This can be very difficult to clean and affects the overall appearance of the panels.

In contrast the Nano panel solves this problem. Nano panels have low coating tension, which makes it difficult for dust or pollution to adhere to its surface and rain is its self-cleaning property. As a result, the Nano panel is able to save you money on cleaning expenses. Another example of the Nano panels effective cleaning properties is its ability to rub away ink pen marks.

Raw Materials

Basis Aluminum: High strength aluminum alloy

Plastic Core: Non-toxic, low density polyethylene

Surface Coating: PVDF, Nanometer pain

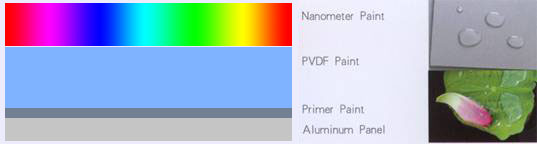

Nanometer aluminum composite panel structure

Nano principle: We coat the self-cleaning protection layer on the surface

of the PVDF paint. It can insulate the dust and decompose the organic contamination and then become true self-cleaning properties.

- Nano (PVDF) Physical Parameter of Nano (PVDF) Panel

Testing Item |

Standard |

Result |

Unit weight |

ASTM D792 |

T4mm=5.5kg/m3 |

Thermal expansion |

ASTM D696 |

24-28 |

Thermal deformation temperature |

ASTM D648 |

115oC |

Thermal Conduction |

ASTM 976 |

0.102kcal/m.hroC |

Flexural rigidity |

ASTM C393 |

14.0*10Λ5 |

Impact resistance |

ASTM D732 |

1.640kgf |

Adhesive strength |

ASTM D903 |

0.77kg/mm |

Flexural Elasticity |

ASTM D790 |

4032kg/mm2 |

Shear resistance |

ASTM D732 |

2.7kgf/mm2 |

Fire propagation |

ASTM E84 |

QUALIFIED |

Wind-resistance |

ASTM E330 |

PASSED |

Properties against water |

ASTM 331 |

PASSED |

- Parameter of Nanometer Coating

(PSB tests according the AAMA2605-05 standard)

Test Item |

IBOND Result |

AAMA2605-05 Requirement |

|

|

|

|

|

|

|

|

|

|

|

|

Impact resistance |

No removal of film |

No removal of film |

|

|

|

|

|

|

|

|

Mortar dislodged easily |

|

|

|

|

|

|

|

|

|

- Economic: We adopt high-quality of paint. So the dust is difficult to adhere on the surface of the panel. It can be easily brushed away by rain to come true through it’s self cleaning properties. As a result this can save you money for cleaning expenses.

- Environment Protection: Superior aging resistance, no coating changes, no pollution, anti-acid, anti-alkali, solvent resistant.

- Durable: It is more durable, weather resistant, temperature resistant, friction resistant, pollution resistant, aging resistant compared with traditional PVDF panel.

- Recycle: We are able to separate the aluminum and polyethylene for recycling purposes.

Specification

Thickness: 3-6mm

Recommended: 3mm, 4mm

Width: 1000 – 1575mm

Recommended: 1220mm, 1250mm, 1500mm

Length: Maximum 5800mm

Recommended: 2440mm, 3050mm, 4050mm